Optimizing CNC Machine Tool Performance through Laser Alignment and Calibration

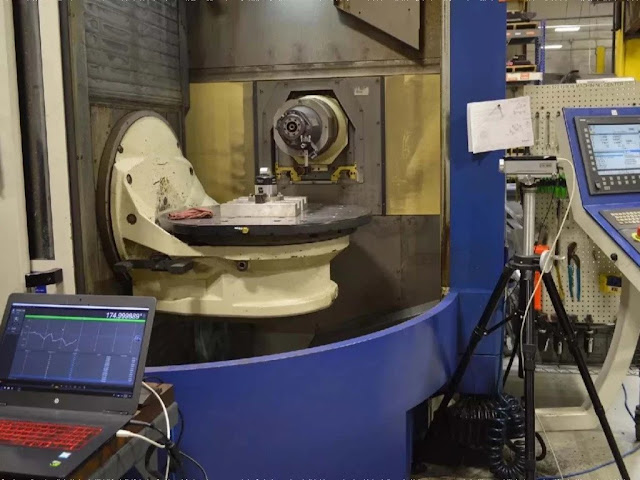

Computer Numerical Control (CNC) machine tools have revolutionized the manufacturing industry by enabling precise and automated machining processes. However, to achieve high levels of accuracy and productivity, it is essential to ensure that CNC machine tools are properly aligned and calibrated. Among the various methods available for alignment and calibration, laser technology has emerged as a popular and effective tool. In this blog, we will explore how CNC machine Tool laser alignment and calibration can optimize CNC machine tool performance and benefit the manufacturing process. CNC Machine Tool Laser Alignment Laser alignment is a technique used to measure and adjust the geometric alignment of CNC machine tools, including axes, spindles, and tool holders. It involves the use of laser beams to establish reference points and measure the relative positions of machine components. By aligning the machine tool accurately, it ensures that the machining process occurs along the inten

.jpg)