Best CNC Machine Tool Laser Calibration Services To Boost Your Business

Accuracy and repeatability are

important for any machine application. If your CNC machine tool is running with

an error, it is time to look for the best CNC Machine Tool Laser Calibration Services. M A M Tech Inc. optimizes your equipment potential and provides a

durable linear position sensor calibration and geometric calibration as per

your machine tool requirements. It has been in this business since 1982 and

offers high-quality and long-lasting alignment and calibration on various

machine tools.

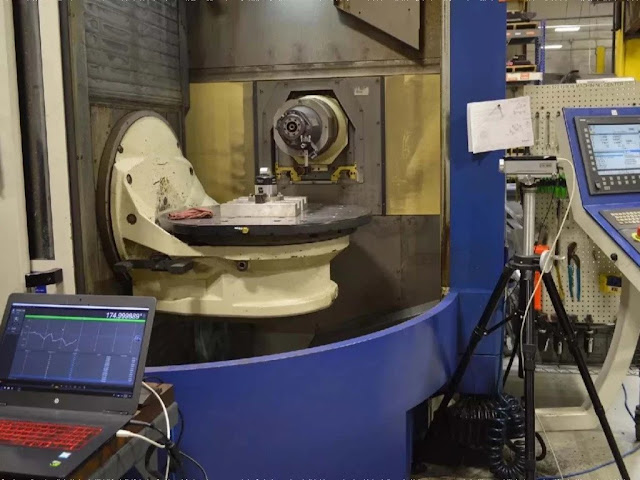

What is CNC Machine Tool Laser Calibration?

A machine tool laser calibration

system reflects a modulated laser beam onto a movable target (mirror). The beam

detects and processes to determine the position of the CNC serving loop's

accuracy. The calibration process ensures your CNC machine tool’s accuracy,

repeatability, tight tolerance, and peak performance, improving product quality

and enhancing your business's bottom line.

The right calibration and repair

of machine tools provide the following advantages:

·

Simplicity in Operation

·

Production of Quality Products at an affordable

price

·

Reduced setup time

·

Good Portability

Reasons For CNC Machine Tool Laser

Calibration

CNC (computer-numerical control) machine

tools have revolutionized the manufacturing sector. The CNC machine has reduced

labor and replaced operator-required equipment. Choose the CNC machine tool

laser calibration and boost excellent, efficient, and precise manufacturing

capabilities. This ideal machine typically produces a shaping machine, center

lathe, grinder, router, or vertical miller.

The liner positioning, vertical and lateral

straightness, pitch, roll, and yaw all have the possibility for errors in their

X, Y, and Z coordination. A machine tool can cause errors if it is not

perfectly aligned and square with XY, YZ, and XZ junctions. If they are not

caught and prevented, these errors can diminish the quality of casting,

assembly, tooling, and composites for any project.

The following are some compelling reasons

to have your machine tools calibrated to automated precisions:

Acceptance Testing

Acceptance testing is similar to laser

tracker certification. It is necessary to compare the performance of OEM’s

stated specifications to validate the machine tool’s performance. The best

machines for acceptance testing are those that have recently been installed or

that have not been used on recent projects. Before any valuable machining

repair, the objective of finding errors is a must.

Preventative Maintenance

Unlike acceptance testing, preventative

maintenance looks to identify and eliminate error sources before they start to

impact production outcomes. Preventative maintenance on machine tools entails

performing regular, scheduled checks on machines even if they don't exhibit

obvious errors. You can take the example of changing the oil in a car by

catching errors to avoid costly downtime.

Measuring accuracy and CNC machine tool laser calibration services are equivalent to many large and more expensive systems. All systems are flawlessly calibrated, and we provide detailed calibration certificates traceable to international length standards. Visit the site of M A M Tech Inc for more info!

Call us at 1-313-530-5083 or visit our website: https://measurementandmachine.com

.jpg)

Comments

Post a Comment