Optimizing CNC Machine Tool Performance through Laser Alignment and Calibration

Computer Numerical Control (CNC) machine

tools have revolutionized the manufacturing industry by enabling precise and

automated machining processes. However, to achieve high levels of accuracy and

productivity, it is essential to ensure that CNC machine tools are properly

aligned and calibrated. Among the various methods available for alignment and

calibration, laser technology has emerged as a popular and effective tool. In

this blog, we will explore how CNC machine Tool laser alignment and calibration can optimize CNC machine tool

performance and benefit the manufacturing process.

|

| CNC Machine Tool Laser Alignment |

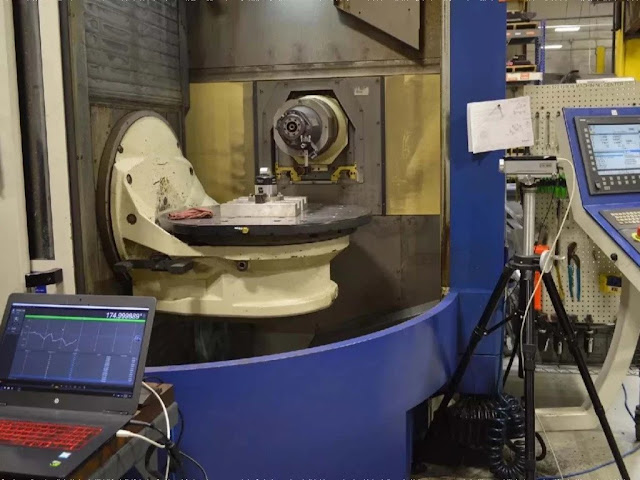

Laser alignment is a technique used to

measure and adjust the geometric alignment of CNC machine tools, including

axes, spindles, and tool holders. It involves the use of laser beams to

establish reference points and measure the relative positions of machine

components. By aligning the machine tool accurately, it ensures that the

machining process occurs along the intended path, resulting in precise and

consistent part dimensions. Laser alignment also helps prevent premature wear

of machine components, reduces downtime, and minimizes scrap rates.

Similarly, CNC Machine Tool calibration is the process of adjusting and verifying the accuracy of CNC

machine tools by comparing their actual performance with the desired

performance. Calibration involves measuring machine tool parameters, such as

positioning accuracy, repeatability, and geometric errors, and making

adjustments to bring them within acceptable tolerances. Proper calibration ensures

that the CNC machine tool performs as intended, producing parts with consistent

quality and dimensional accuracy.

Benefits of CNC Machine Tool Laser Alignment

and Calibration

One of the significant benefits of laser

alignment and calibration is improved accuracy. CNC machine tools operate based

on predefined tool paths, and any misalignment or calibration error can result

in deviations from the intended dimensions. Laser alignment ensures that the

machine tool components are precisely positioned, eliminating any errors caused

by misalignments. Calibration ensures that the machine tool parameters are

accurately adjusted, minimizing deviations in part dimensions and improving

overall accuracy.

Another benefit of laser alignment and

calibration is increased productivity. Accurate alignment and calibration help

reduce machine downtime caused by unexpected breakdowns, tool wear, or part

rejections. It minimizes the need for trial and error adjustments during setup,

resulting in faster and more efficient machining processes. High precision

alignment and calibration also allow for higher cutting speeds and feeds,

maximizing material removal rates and productivity.

Furthermore, laser alignment and CNCmachine tool calibration can extend the lifespan of machine tools.

Misalignments and calibration errors can cause undue stress on machine

components, leading to premature wear and tear. Regular laser alignment and

calibration can prevent such issues by maintaining the machine tools within

their optimal operating parameters. This helps to prolong the lifespan of the

machine tools, reduce maintenance costs, and maximize their return on

investment.

Moreover, laser alignment and calibration

can enhance the quality of machined parts. Alignment errors or calibration inaccuracies

can result in part defects, such as out-of-tolerance dimensions, uneven

surfaces, and poor surface finishes. Accurate alignment and calibration help

ensure that the machined parts meet the desired specifications consistently.

This can help manufacturers avoid costly rework, scrap, or customer rejections,

and maintain high-quality standards.

Conclusion

CNC

Machine Tool laser alignment and calibration are

critical techniques for optimizing CNC machine tool performance. They

contribute to improved accuracy, increased productivity, extended lifespan of

machine tools, and enhanced part quality. Regular laser alignment and

calibration can help manufacturers achieve higher levels of precision,

efficiency, and profitability in their machining processes. It is essential to

work with experienced and qualified technicians of Measurement and Machine

Technology who are trained in laser alignment and calibration to ensure

accurate and reliable results. Investing in laser alignment and calibration is

an investment in the long-term success of CNC machining operations.

For more info Call us: 1-313-530-5083 or Visit our Website: https://www.measurementandmachine.com

Comments

Post a Comment